Dynamic Lift System (DLS)

Is it possible to get 5 days of roadwork done in 4 days?

Take a look and see for yourself!

The setup and takedown of work zone lane closures with cones and vertical panels can be an arduous, time consuming dangerous task. J-Tech's innovative Dynamic Lift System (DLS) trucks are designed to help reduce the time it takes your workers to setup and takedown temporary work zone lane closures.

If you save two hours a night on a multiple mile setup and retrieval, then in four days you have an extra eight hours! Reducing your setup time gives your staff more time and energy to do the project at hand.

The J-Tech Highway Safety

DLS PRO-TIP:

-

WORK SMARTER!

Use the DLS method to safely deploy and retrieve vertical panels and cones. -

ENHANCE EFFICIENCY!

The DLS mechanical advantage reduces time and effort of physical work zone setup. -

REDUCE RISK!

Decrease the risk of injury and fatigue caused by repetitive lifting and twisting of heavy unwieldly channelizing devices.

Here’s how it works…

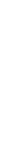

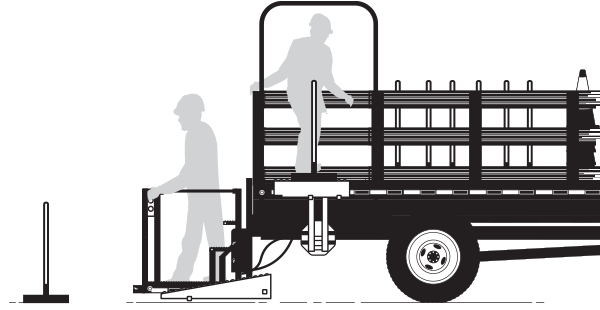

The DLS system is a hydraulic lifting system made up of two worker stations; a receiving/deploying station at the rear of the truck bed and a safety basket (lower platform), close to the road for easy deploying or retrieving of cones and vertical panels.

The worker tilts the cone or panel as it comes near the roller panel and guides it to the lift which conveys the cone or panel to the worker up in the bed of the truck. Both workers have safety rails and easy access to the lift controls.

J-Tech DLS has a full safety package but offers more choices of optional features, including lighting accessory packages, DVR Camera Systems, message and/or arrow boards, underbody toolboxes and sign/cone racks.

Let us build a standard J-Tech DLS or one with customizations to make a highway safety vehicle that fits your unique needs and enhances safety for your work crew.

Let the J-Tech DLS do the heavy lifting!

1. Do you currently set up temporary work zones?

Do you put out cones and vertical panels from a tandem axle trailer, walking on the roadway, standing on lift gates, or from manpods/safety pods on a stake body truck?

Safety starts by preventing accidents and avoiding “industry known” dangers; J-Tech DLS helps highway construction crews set channelizing devices (cones and vertical panels) from the safety of the truck, not walking on the roadway where they are closer to harm’s way.

2. Do you set patterns the way you have always set patterns?

Is there a smarter method to deploy and retrieve cones and vertical panels?

J-Tech DLS drastically reduces setup and takedown time. If you devote less time to setup and teardown, you have a longer block of time in the middle to get your core roadway project done.

3. Do you have Workman’s Compensation Claims and injuries?

Is there a way to reduce repetitive and strain injuries from picking up work zone channelizing devices?

Back twisting and strain come from repetitive lifting and twisting while placing heavy vertical panels and cones on the roadway or retrieving them to the bed of the truck.

INDUSTRY DANGER: Nighttime hidden employee back-over.

SOLUTION: A DLS truck cannot accidentally back over workers picking up cones if they are working from the safety of the J-Tech Safety Basket.

INDUSTRY DANGER: Falls off truck.

SOLUTION: In the J-Tech DLS, your workers have railings to help prevent falls, unlike the “lean over the tailgate” method.

J-Tech Highway Safety is standing by to make your operations safer!

REACH OUT TO THE CHANNELIZING EXPERTS TODAY HERE OR BY CALLING 610-458-4334!

Full-Size Attenuator Trucks

Full-Size Attenuator Trucks